Gasifier Cookstoves

What are Gasifier Cookstoves?

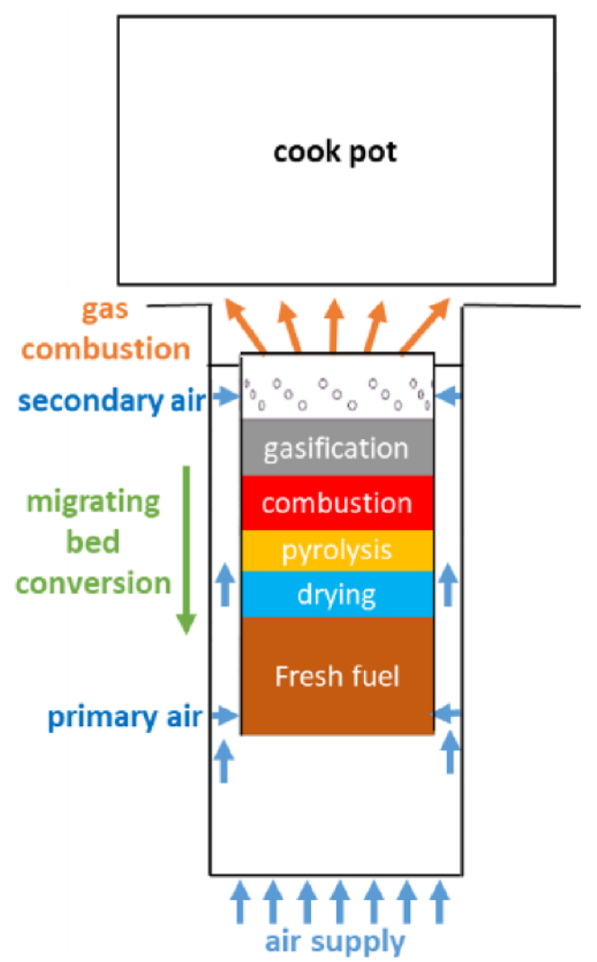

Gasifier Cookstoves convert solid biomass into as combustible gas that is burning without generating smoke. They represent the cleanest and most efficient way to use solid biomass as a fuel.

This is achieved by splitting the combustion process of solid biomass into two zones. The first zone produces combustible gases from the solid biomass, in the second zone these gases are burned using forced preheated air. In both zones the oxygen supply is optimized to create a combustion that is both complete and efficient. For this purpose a controlled airflow is essential which, in turn, can best be achieved with the help of a small fan – hence the specification “forced draft”.

First Stage

Gasification of biomass:

The fuel in the gasifier is set on fire with a bit of ethanol. The holes on the

bottom of the gasifier allow just enough air (the so-called primary air) to

enter the chamber to sustain a weak combustion. This combustion releases

enough heat to turn part of the solid biomass to combustible vapors, called

wood gas. Controlling the airflow to this stage controls the heat of the

limited combustion and thus the amount and composition of the wood gas

that is released.

Second Stage

Combustion of gases:

The hot wood gas rises to the top of the combustion chamber and is mixed

there with air, entering through the holes at the top (the so-called secondary

air). This air is preheated by flowing alongside the hot combustion chamber.

The resulting mixture of wood gas and hot air burns like a gas flame without

any generation of smoke.

Source: Scharler etal 2021, CC BY 4.0.

Basic Design and Function

Gasifying stoves have an inner (metal) cylinder with an open top and holes for air supply at the bottom and near the top. This cylinder, the combustion chamber, is enclosed with another cylinder with a larger radius, leaving a gap for air to pass through. A small fan is connected to this gap and drives combustion air through the holes into the combustion chamber.

A rechargeable battery drives the fan and most stove models have a regulator for the fan speed to control heat generation.

Sometimes even a Bluetooth or WIFI connection is integrated into the stoves to enable Internet of Things capabilities, such as monitoring of operation or paygo functionalities. This enables innovative financing models or highly accurate carbon accounting for carbon credits.

See how they are operated: